The electronics industry is a rapidly growing field where the quality, precision, and certifications of sealing and insulation materials are crucial. NMC Cellfoam offers insulation and sealing solutions that meet even the strictest requirements of the electronics industry.

Packaging, Sealing, and Thermal Insulation

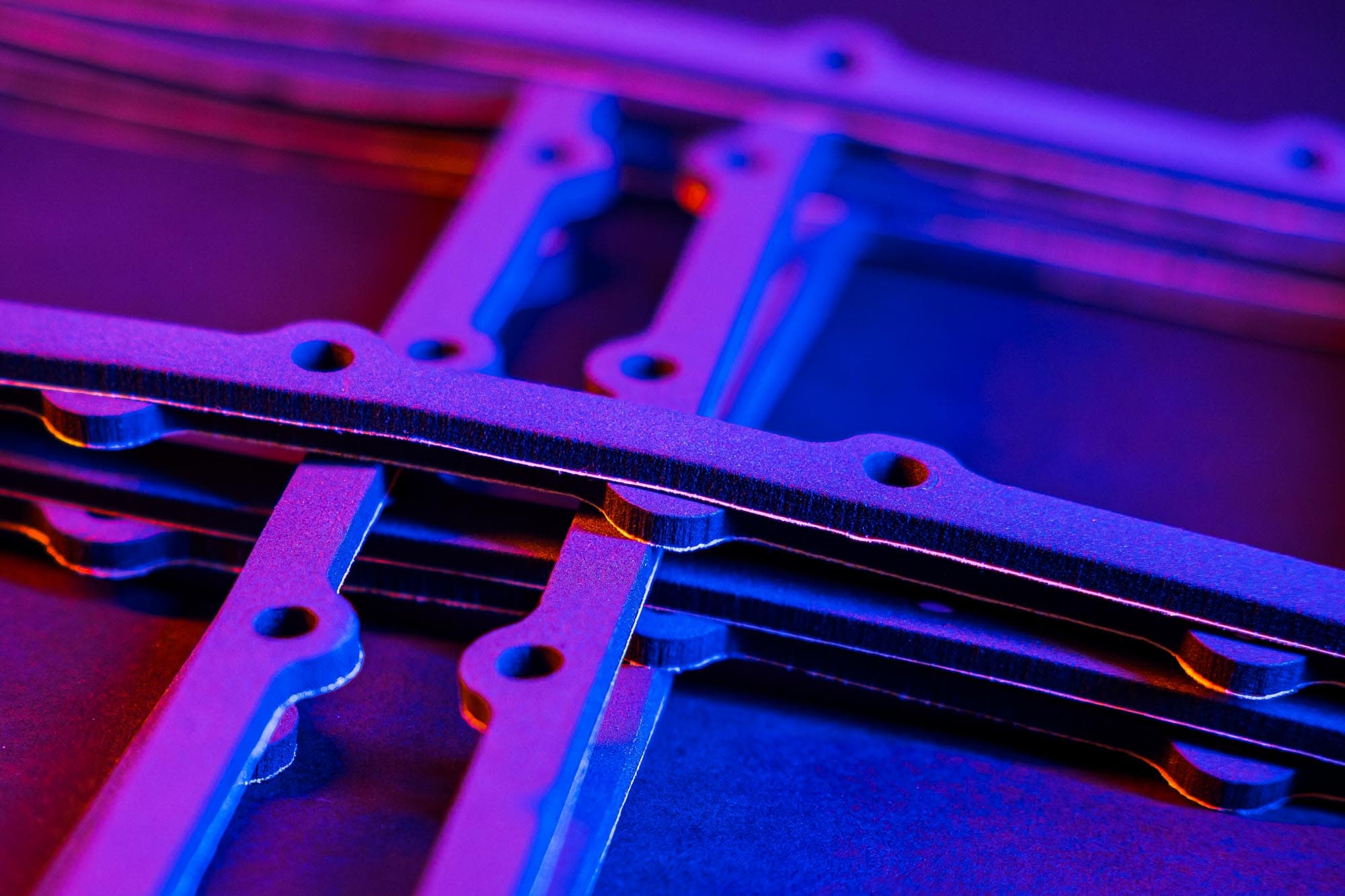

The electronics segment within the NMC Cellfoam portfolio is very broad and diverse. The main solutions are related to packaging, sealing, and thermal insulation of large electronics cabinets.

“For example, filtration solutions may be needed in engines where conditions and requirements vary greatly. Sometimes dust-tightness is sufficient, while other times materials must meet strict certification requirements,” says Area Sales Manager Kimmo Kylliö NMC Cellfoam, Finland.

Our customer base includes large national players in the Nordic countries, manufacturing everything from fine electronics to engines.

Precision and Quality Assurance are Key

“We work with components inside small devices. Smaller seals are often part of fine electronics assemblies, such as sealing displays,” describes Engineering Manager Mikko Sola, NMC Cellfoam, Finland. Sometimes we work outside the components, such as sealing solutions for large engines. In these areas, precision and material choices are critical for product functionality and safety.

“The material requirements of the electronics industry are very strict. In most cases, Yellow Card™ approval is needed, indicating that the material meets the safety and quality requirements set by UL Solutions. For example, UL 94 fire rating and other fire-related approvals are part of this process. Practically, 90-95% of fine mechanics materials require such approvals, and this is one of our strengths,” Sola continues.

Gradually, PPAP quality documentation (Production Part Approval Process) is also required in the electronics industry. “Quality is a comprehensive matter for us, and we have all the necessary tools to verify quality,” Sola emphasizes.

Top-notch Material Knowledge

Electronics differ as a segment from other NMC Cellfoam areas of expertise in that customers often have ready-made plans already at the request for quotation stage.

“Our task is to select the right material for these requirements, and if such a material is not immediately found, we look for alternatives. Most often, a solution is found,” describes engineer Juhani Kivinen, NMC Cellfoam, Finland.

“We know the properties and availability of materials. Our collaboration is based on strong interaction and customer service readiness. Juhani is an important partner for me in engineering, and if a challenge arises, we immediately go through it and find a solution. We do not leave the customer waiting or in uncertainty,” Kylliö emphasizes.

Responsibility and Regulation are Increasing

The importance of responsibility is constantly growing, especially thanks to EU regulation. “PPAP documentation and responsibility requirements are increasingly important. We already have a good grasp of carbon footprint calculation and can provide our customers with transparent information about the environmental impact of our products,” Kylliö notes.

With the EU deforestation regulation, the traceability of certain products has become a key factor. “Customers want to know the precise origin of all components and be able to track their supply chain. In packaging solutions, recyclability has become one of the significant factors, and we have developed solutions that meet this need,” Sola adds.

Future Development Directions

Kylliö sees the company’s strength particularly in sealing and packaging. “Our core expertise is in sealing and packaging solutions. Conveyor trays used to transport fine mechanics are good example.”

Material development is a key part of the future. “Thermal conductive materials, such as thermal pad solutions, are a particularly interesting area. These are already moving towards highly specialized materials, but the potential is great, even at the circuit board level of the electronics industry,” Kylliö assesses.

Finally, Sola emphasizes the importance of material choices: “In the electronics segment, material selection is critical – the right material for the right solution is the foundation of everything. NMC Cellfoam’s material selection and operational readiness are excellent.